We offer comprehensive research & characterization solutions before, during and after maintenance or decontamination and decommissioning operations, particularly for:

Radiological research operations (on-site measurements)

Precisely characterize the radiological state of local, equipment or land

Characterizing the waste, effluents and products of nuclear facilities or contaminated

sites (on-site and laboratory measurements)

Checking the final level of radiological cleanliness

Our laboratories in the U.S.

Veolia Nuclear Solutions operates two radioactively licensed facilities in Richland, Washington: the Research Center (tritium) and the Separation Development Lab (located at APEL). The laboratories are customer and application focused. We offer services to conduct treatability studies and help predict system performance for any client application.

Our U.S. Laboratories have:

adapted methods for many types of wastes Sorption (Adsorption, Absorption and Ion Exchange) testing equipment

Liquid Scintillation Counting

Partners with accredited laboratories in the United States to provide certified analytical results to customers

Our laboratory in France

Veolia Nuclear Solutions owns and operates a 500 m² radiological laboratory. Created in 2013, this laboratory, situated near Lyon, France, has a COFRAC (COmité FRançais d’ACcréditation) certification for 11 complex analysis methods (accreditation COFRAC Testing 1-5750. scope available on www.cofrac.fr).

COFRAC is recognized for testing activities by EA (European cooperation for Accreditation), ILAC (International Laboratory Accreditation Cooperation) an IAF (International Accreditation Forum). This laboratory can run complex tests requiring radiochemical separations, long count times and a low level of ambient radiation.

Our French laboratory's capacities:

10,000 analyses per year

Complex analyses (α, β counting, α and γ Spectrometry, Liquid Scintillation, ICP MS – metal analysis, Analyses requiring preparation and/or chemical Separations)

Adapted methods for all kinds of waste (liquids, solids, aerosols)

Validated methods (participation in international aptitude and intercomparison tests)

Validated methods (participation in international aptitude and intercomparison tests)

Main equipment available:

- Preparation equipment for solid samples: crushers, ovens, furnaces, screens, microwave mineralizer, oxydizer, etc.

- Radiochemical separation equipment (liquid-liquid extraction, ion-exchange resins, precipitation, distillation, evaporation, etc.

- Liquid scintillation counter

- γ spectrometry measuring system with a HPGe detector with a wide energy band

- α spectrometry measuring system

- Proportional gas counter

- ICP / MS

A Key Role at Every Step of Nuclear Cleanup Operations

Our Investigation and Characterization team provides solutions before, during and after nuclear maintenance, cleanup or decommissioning operations as:

- Characterization of initial state

- Mapping of installations

- Sampling program

- D&D scenario

- Operators radiation protection

- Waste analysis and control

- Identification, sorting and D&D waste management

- Waste optimization

- Control of final state

- Proof of decontamination achievement

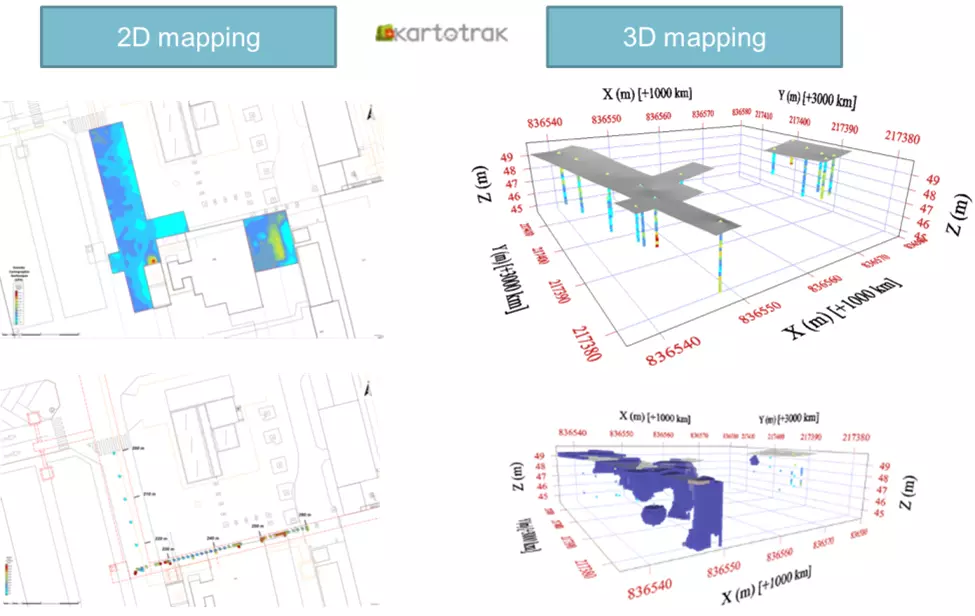

Examples of contamination mapping

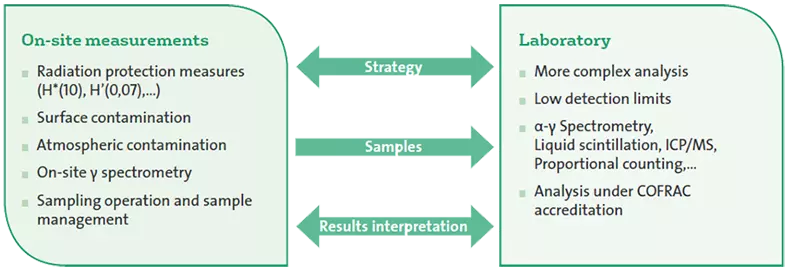

Operational Synergies Between On-site Measurements and Laboratory

Competences, expertise and equipment are integrated in one team, to enable a good reactivity, efficient information and data management but also a complete adequacy between sampling operations and analytical needs.

Thanks to our measuring and characterization expertise, our teams are able to propose a full range of services, from on-site operations to laboratory testing:

• On-site characterization of the situation

• Site investigations and mapping

• Identifying, sorting and managing the waste produced

• Managing and taking samples (coring, boring, etc.)

• Preparation and initial characterization using a mobile laboratory on-site

Competencies, expertise and equipment integrated in one team

* accreditation COFRAC Testing 1-5750. scope available on www.cofrac.fr